Injection Molding Solutions for Hand Cream & Explosive Salt Series Packaging

Description

Technical Expertise & Customization

Material Selection & Compliance:

Hand Cream Packaging: Utilize FDA-approved, chemical-resistant polymers (e.g., PP, PE) to withstand emulsified formulas and frequent squeezing. Options include lightweight, collapsible tubes or ergonomic bottles with anti-slip grips.

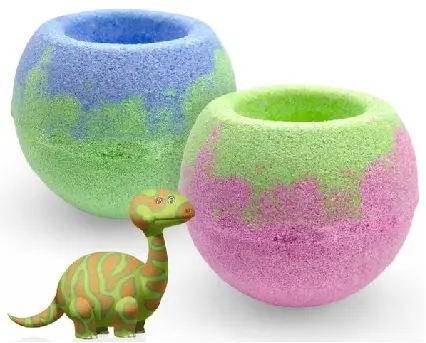

Explosive Salt Containers: Engineer molds for moisture-proof, high-barrier materials (HDPE, PET) with UV protection to preserve product integrity. Incorporate child-resistant caps (CRCs) meeting ASTM D3475 standards for safety.

Mold Design for Functional Integrity:

Leak-Proof Seals: Precision-engineered threads and snap-fit closures for airtight sealing, critical for hygroscopic explosive salt products.

Multi-Layer Structures: For explosive salt jars, design molds with reinforced walls and ribs to resist internal pressure from reactive contents.

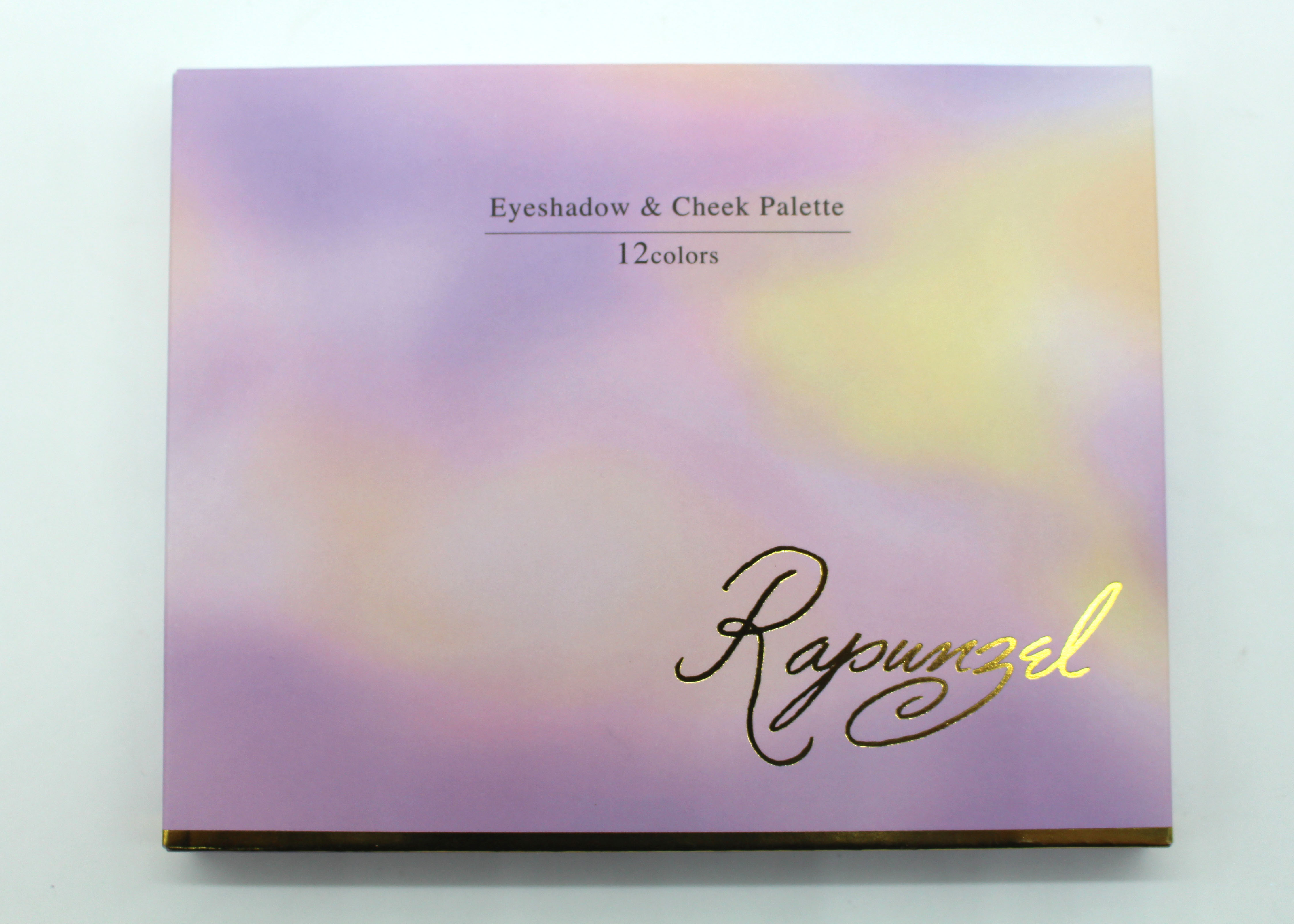

Surface Finishes: Matte or glossy textures via EDM/textured cavities; anti-scratch coatings for premium hand cream dispensers.

Efficiency-Driven Production:

Hot-Runner Systems & Multi-Cavity Molds: Optimize cycle times and reduce waste for high-volume orders (e.g., 64-cavity molds for mini hand cream tubes).

Overmolding Capabilities: Combine soft-touch TPE grips with rigid PP bodies for enhanced user experience.

Quality & Compliance Assurance

Mold Flow Analysis: Simulate filling patterns to eliminate warping or sink marks, ensuring uniform wall thickness for consistent product durability.

Pressure & Leak Testing: Validate containers under extreme conditions to guarantee seal integrity for explosive salt’s reactive properties.

Global Standards: Molds comply with ISO 9001, EU Cosmetics Regulation, and OSHA chemical packaging guidelines.

Sustainability & Cost Optimization

Lightweighting: Reduce plastic usage by 15–20% through structural optimization without compromising strength.

Recyclable/Bio-Based Materials: Offer PCR (post-consumer resin) or PLA options to align with eco-branding goals.

Energy-Efficient Molding: All-electric presses minimize energy consumption and carbon footprint.

End-to-End Services

Rapid Prototyping: 3D-printed molds for functional testing of CRC caps or tube dispensers within 5 days.

Decoration Integration: In-mold labeling (IML) or laser engraving for branding on curved surfaces.

Full Turnkey Solutions: From mold design to assembly (e.g., pump attachment, cap liners).

Why Partner With Us?

Industry-Specific Knowledge: Proven experience in cosmetics, personal care, and chemical packaging.

Scalability: Seamlessly transition from pilot batches to mass production.

Innovation-Driven: Custom solutions for unique challenges, such as explosive salt’s reactivity or hand cream’s viscosity demands.

description1