Precision Injection Molding Solutions for Children’s Water-Based Nail Polish Packaging

Description

Expertise in Child-Safe Packaging Design:

Mold Engineering for Miniaturized Components:

Our advanced CAD/CAM-driven designs optimize molds for small, intricate parts like nail polish caps, bottles, and brush applicators. Tight tolerances (±0.01mm) ensure leak-proof seals and consistent fitment, critical for water-based formulas prone to drying or leakage.

Child-Resistant yet User-Friendly Features:

Molds are engineered for compliant closures (e.g., push-and-turn caps) that balance safety (meeting ASTM/EN child-resistance standards) with ease of use for parents. Ergonomic brush handles and lightweight bottle designs enhance tiny hands’ grip during play.

Material Compliance & Durability:

We select FDA-approved, food-grade polymers (e.g., PP, PETG) resistant to water-based chemicals, ensuring packaging remains crack-free, non-reactive, and durable through repeated use. Options include recyclable or bio-based resins to align with eco-friendly brand values.

Efficiency-Driven Production:

Multi-Cavity & Hot-Runner Molds: High-cavitation molds (32+ cavities) paired with hot-runner systems maximize output while reducing material waste and cycle times—ideal for cost-effective, large-scale orders.

Rapid Prototyping: Accelerate time-to-market with 3D-printed mold prototypes for design validation, followed by hardened steel production molds built for 1M+ cycles.

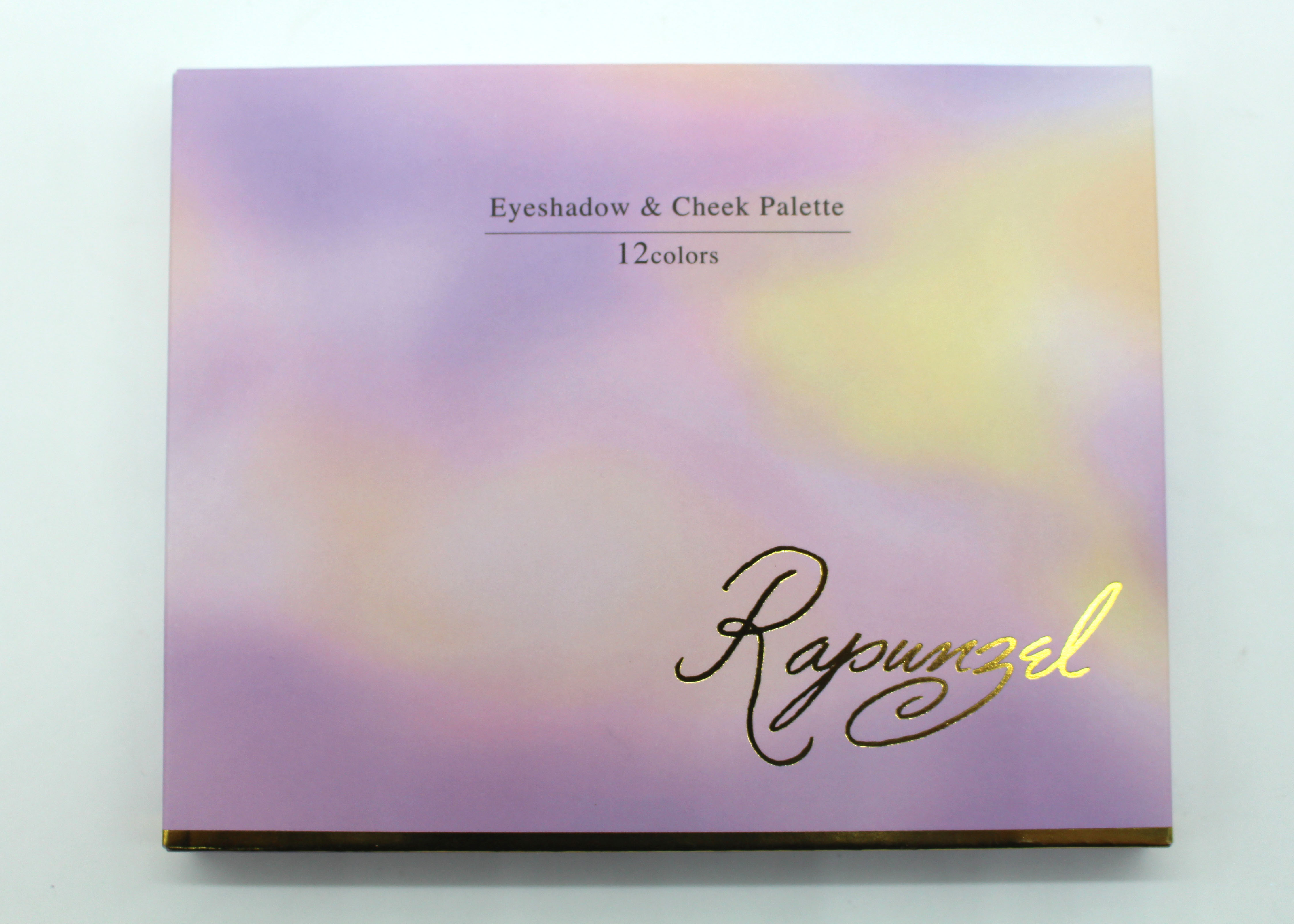

Surface Finish Customization: Textured or glossy finishes, sparkle effects, and branded logos are achieved through precision EDM or laser etching, enhancing shelf appeal for playful, child-centric aesthetics.

Quality Assurance for Flawless Output:

Mold Flow Analysis: Simulate injection processes to eliminate defects like sink marks or warping, ensuring uniform wall thickness for lightweight yet robust bottles.

Strict Compliance Testing: Molds are validated to meet global safety standards (CPSIA, EU Toy Directive) and undergo rigorous T0 sample inspections, pressure tests, and drop tests.

Sustainability in Molding:

Our energy-efficient presses and regrind material systems minimize carbon footprint, while designs prioritize lightweighting to reduce plastic use without compromising durability.

Why Partner With Us?

Industry-Specific Experience: Proven expertise in cosmetics, toys, and child-safe packaging.

End-to-End Support: From mold design to post-molding assembly (e.g., brush insertion, labeling).

Scalability: Seamlessly transition from small batches to high-volume orders.

description1