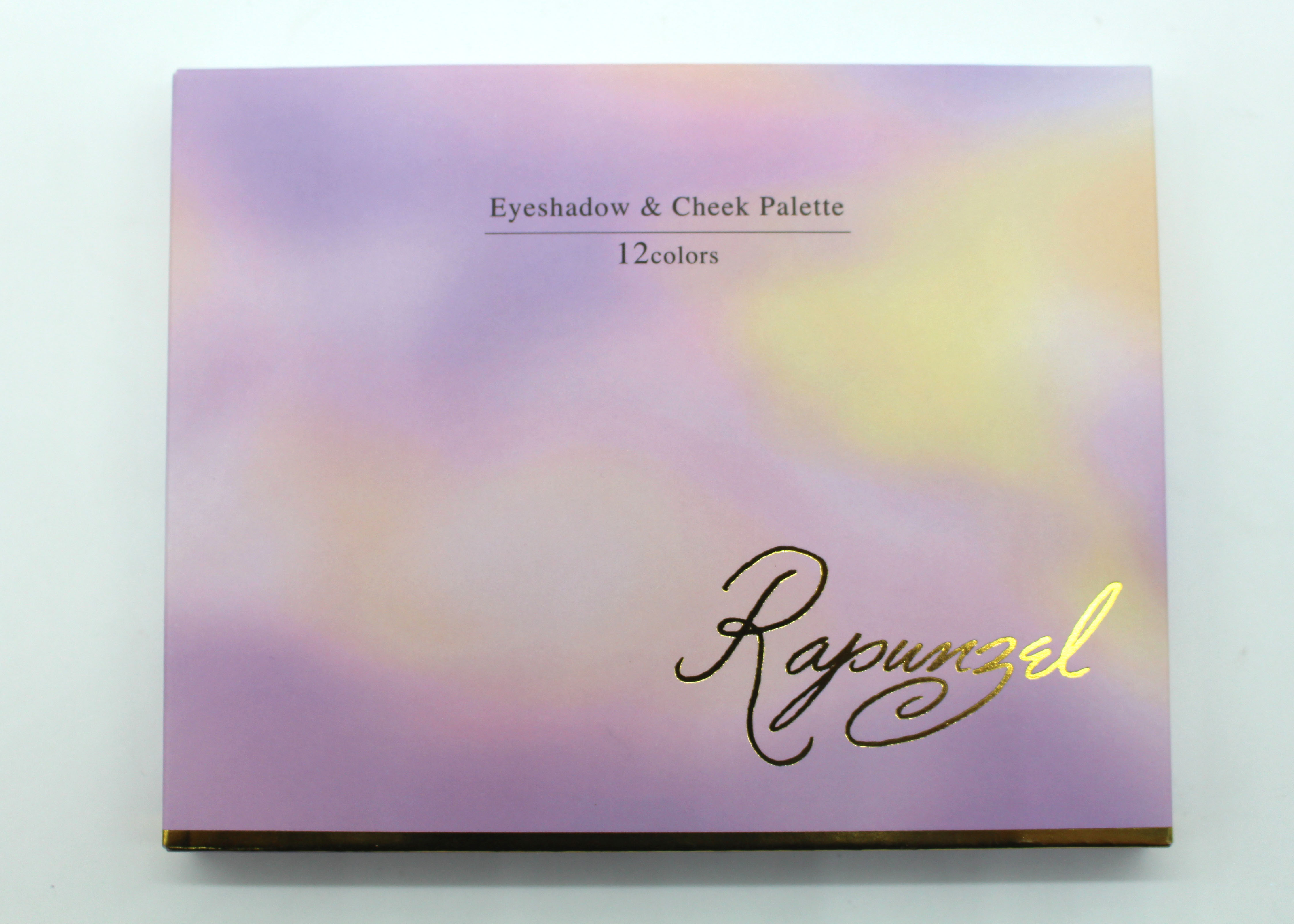

Precision Injection Molding Solutions for Eyeshadow & Blush Series Packaging

Description

Technical Capabilities & Customization

Complex Geometry & Multi-Cavity Molds:

Design and fabricate molds for slim, lightweight compacts with precise internal partitions to separate multiple color pans (e.g., 6–12 eyeshadow trays).

Utilize multi-cavity molds (up to 48 cavities) with hot-runner systems to maximize production efficiency and minimize material waste.

Achieve tolerances within ±0.01mm for seamless hinge mechanisms, magnetic closures, and snap-fit components critical for premium user experience.

Material Expertise:

Recommend FDA-compliant, chemical-resistant polymers (e.g., ABS, PMMA, or recycled PET) to ensure compatibility with pressed powder formulas and long-term durability.

Offer matte or glossy finishes via textured mold surfaces or post-processing (e.g., IMD/INS films) to enhance brand aesthetics.

Eco-Conscious Production:

Optimize wall thickness through mold flow analysis to reduce plastic usage while maintaining structural integrity.

Support sustainable initiatives with bio-based resins (PLA) or recycled materials for eco-friendly packaging.

Quality-Driven Manufacturing Process

Advanced Tooling:

CNC-machined steel molds with hardened cores (HRC 52+) ensure longevity (>1M cycles) and resist wear from abrasive powder fillers.

Surface Perfection:

Mirror-polished cavities and precision EDM/etching eliminate surface defects (sink marks, flow lines), ensuring smooth, scratch-resistant finishes for high-end compacts.

Safety Compliance:

Molds are validated to meet EU Cosmetics Regulation (EC 1223/2009) and FDA standards, with rigorous testing for airtight seals to prevent powder contamination.

End-to-End Support

Rapid Prototyping: 3D-printed mold inserts for design verification and sample approval within 7–10 days.

In-House Finishing: Decoration services (UV coating, metallization) integrated into molding cycles for cost-efficient branding.

Scalable Production: From small batches for limited editions to high-volume orders with <48-hour turnover.

Why Choose Us?

Cosmetics Industry Focus: Proven track record in producing molds for global beauty brands.

Zero-Compromise Precision: Ensures consistent color pan alignment, secure closures, and premium tactile feel.

Cost Efficiency: Reduced cycle times and material waste via AI-driven process optimization.

Transform Your Vision into Reality

Whether it’s a minimalist blush case or a multi-tiered eyeshadow palette, our injection molding solutions combine innovation, reliability, and compliance to elevate your product’s appeal.

Contact us today to discuss your project!

description1