Precision Injection Molding Solutions for Lipstick & Lip Gloss Series Packaging

Description

Technical Expertise & Customization

Complex Component Design:

Lipstick Cases: Engineer molds for ultra-slim, twist-up mechanisms with tolerances ±0.005mm, ensuring smooth rotation and precise alignment of bullet shapes.

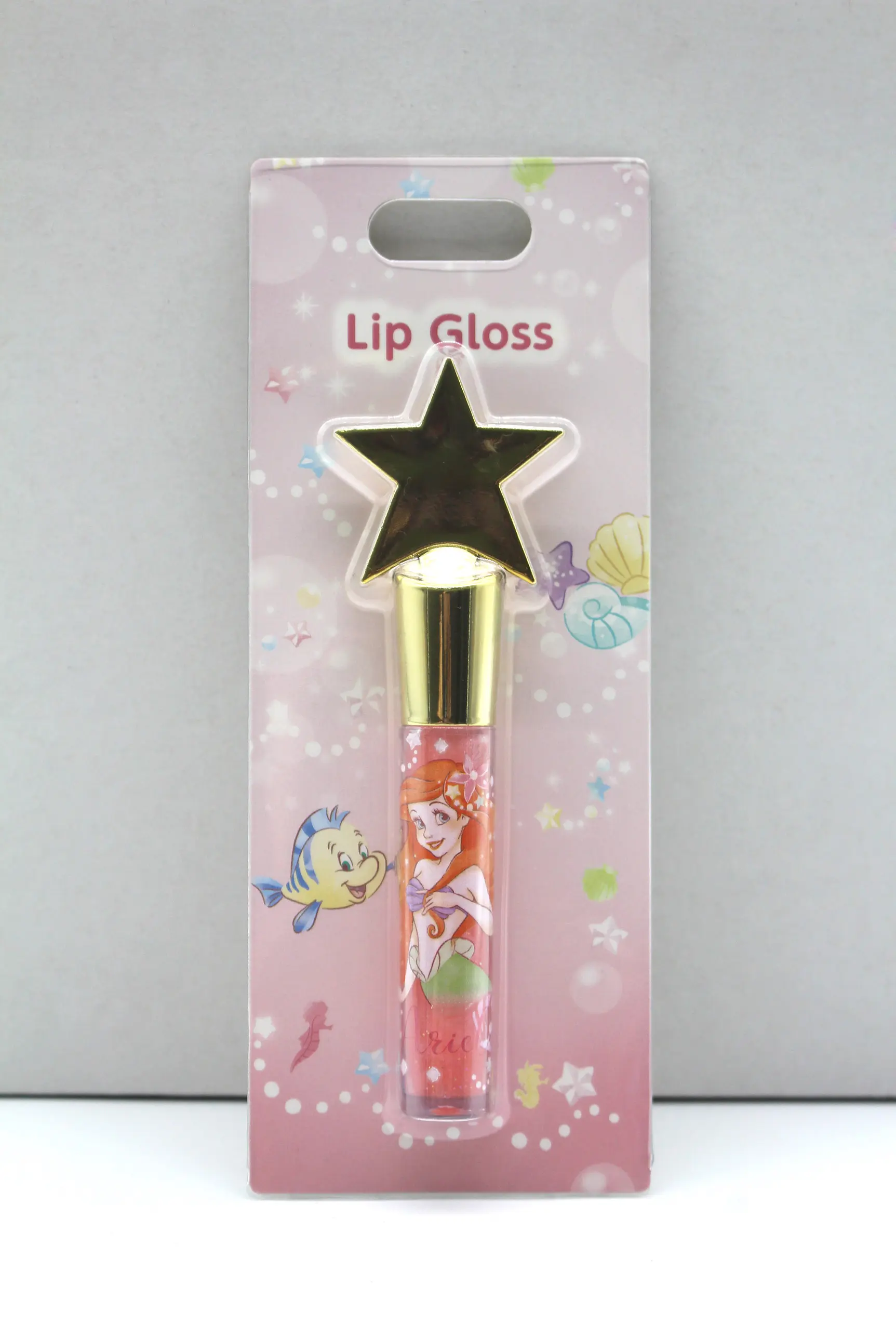

Lip Gloss Components: Design leak-proof bottles, angled applicator brushes, and snap-fit caps with integrated brush slots for user convenience.

Multi-Material Solutions: Overmold soft-touch TPE grips onto rigid ABS/PP bodies for ergonomic, slip-resistant designs.

Material Innovation:

Use FDA-compliant, non-reactive polymers (e.g., PMMA, PETG) resistant to oils, pigments, and fragrances in lip formulas.

Offer UV-stabilized and anti-scratch resins to maintain glossy finishes and vibrant colors.

High-Efficiency Production:

Multi-Cavity Molds (64+ cavities) with hot-runner systems optimize cycle times for mass production of lipstick tubes or mini gloss sets.

Automated Ejection Systems: Ensure damage-free demolding of fragile components like thin-walled gloss bottles.

Quality & Compliance Assurance

Mold Flow Simulation: Predict and eliminate defects (warping, air traps) in intricate geometries, such as hollow lipstick bases or textured bottle grips.

Functional Testing: Validate twist mechanisms for 10,000+ cycles and perform leak tests under thermal stress (-10°C to 60°C).

Certifications: Molds meet EU Cosmetics Regulation, FDA 21 CFR, and ISO 15378 (pharmaceutical packaging standards) for direct product contact.

Aesthetic Excellence & Sustainability

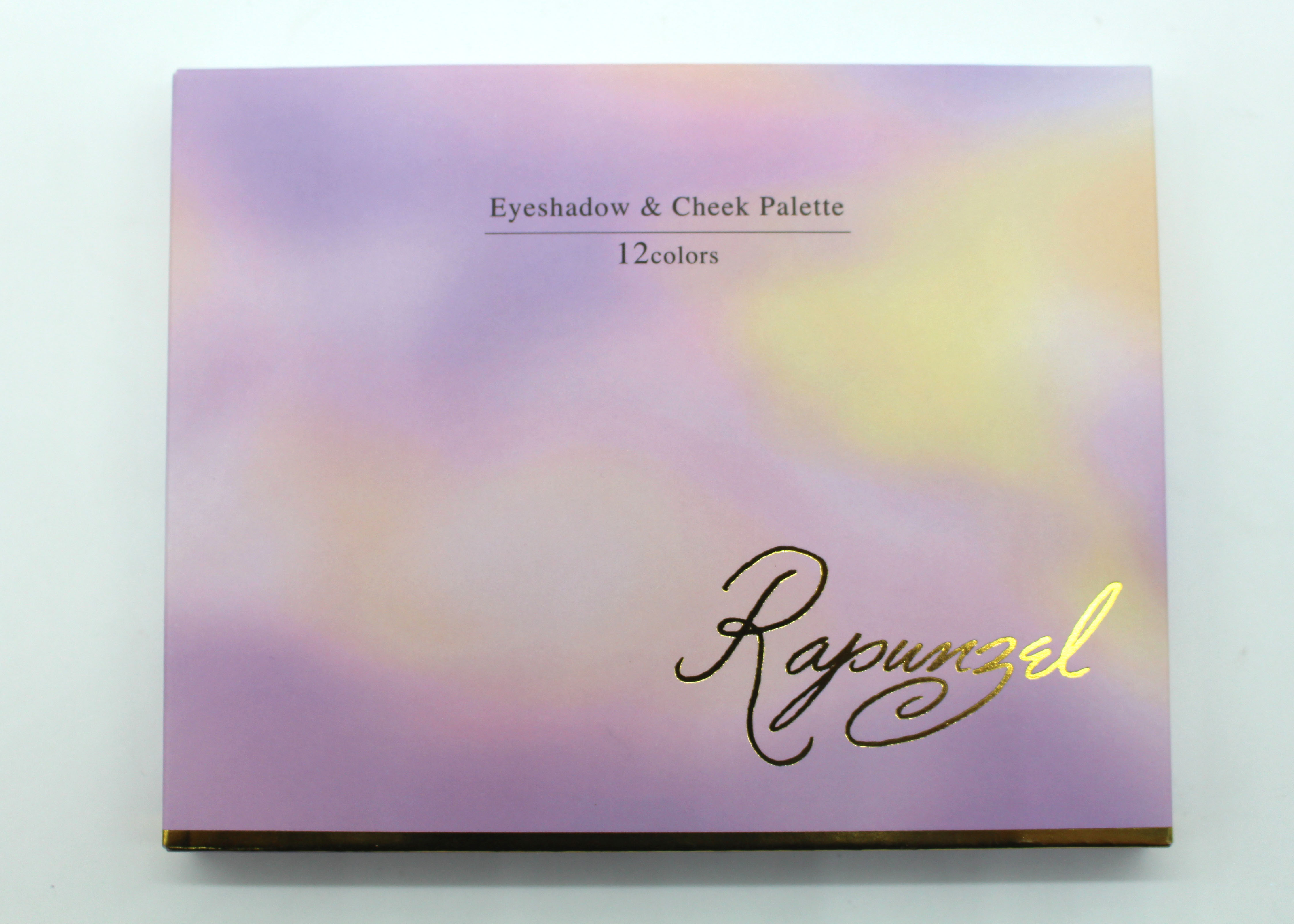

Premium Surface Finishes: Achieve mirror-polished, metallic, or matte textures via EDM, laser etching, or in-mold decoration (IMD) for luxury appeal.

Eco-Conscious Options: Integrate recycled PCR materials or biodegradable PLA for eco-friendly lines without compromising durability.

Lightweighting: Reduce material usage by 25% through structural optimization, lowering shipping costs and environmental impact.

End-to-End Support

Rapid Prototyping: 3D-printed mold trials for functional validation of applicator brushes or magnetic closures within 7 days.

Decoration & Assembly: In-house services include metallic foil stamping, silicone pad printing, and automated brush-head insertion.

Scalability: Support small-batch custom editions or high-volume global launches with consistent quality.

Why Partner With Us?

Beauty Industry Leadership: Proven expertise in luxury cosmetics packaging, from refillable lipstick cases to gradient-effect gloss bottles.

Cost Efficiency: AI-optimized processes reduce scrap rates by 20% and cycle times by 15%.

Innovation-Driven: Solve unique challenges, such as airtight seals for volatile gloss formulas or frictionless twist mechanisms.

Redefine Lip Care Packaging

Whether crafting a sustainable refillable lipstick or a high-shine gloss with precision applicators, our injection molding solutions blend innovation, reliability, and elegance to elevate your brand’s market presence.

Contact us to create packaging that dazzles—inside and out.

description1