Precision Injection Molds & Molded Solutions: Engineered for Excellence

Description

Why Partner With Us?

Advanced Mold Design & Engineering: Our team leverages cutting-edge CAD/CAM software and DFM (Design for Manufacturing) principles to optimize mold designs for functionality, material efficiency, and cycle time reduction. Whether prototyping or high-volume production, we ensure seamless transitions from 3D models to production-ready molds.

High-Precision Machining: Utilizing CNC machining, EDM, and laser etching technologies, we craft molds with tolerances as tight as ±0.005mm, ensuring consistency across millions of cycles. Our expertise covers multi-cavity molds, hot-runner systems, and complex geometries for intricate parts.

Material Expertise: From engineering-grade polymers (ABS, PP, PC) to child-safe, FDA-compliant resins, we select optimal materials to meet mechanical, aesthetic, and regulatory requirements—ideal for industries like toys, healthcare, and consumer goods.

Rapid Prototyping to Full Production: Accelerate time-to-market with our rapid tooling services for prototypes, followed by scalable production molds designed for longevity and minimal maintenance.

Quality Assurance: Rigorous testing, including T0 sample inspections, CMM measurements, and mold flow analysis, guarantees defect-free output and compliance with ISO 9001 standards.

Applications We Serve:

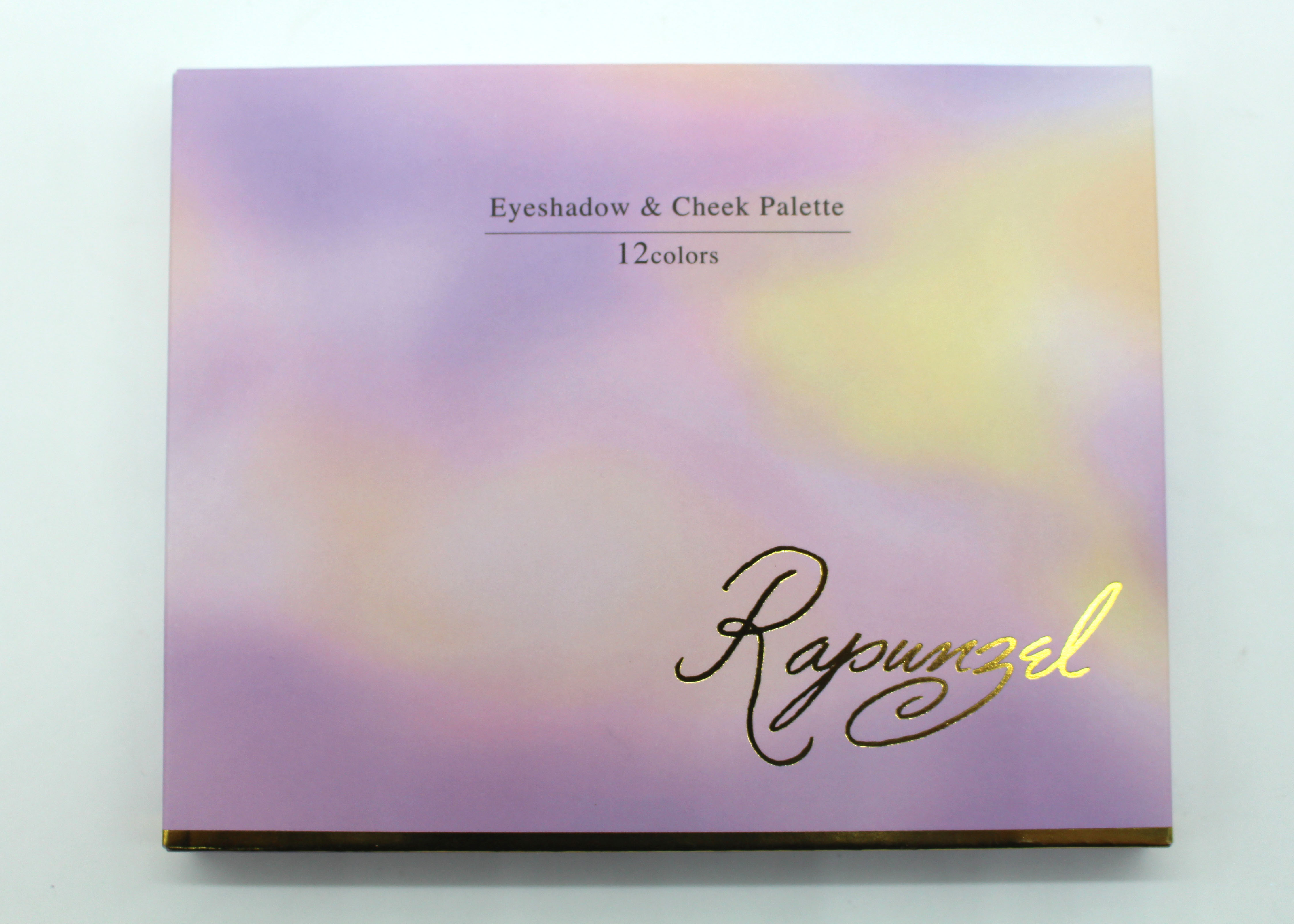

Consumer Products: Durable molds for toys, cosmetics packaging, and household items.

Automotive & Electronics: Precision components with high heat/wear resistance.

Medical Devices: FDA-approved, ultra-clean molds for sensitive applications.

Sustainability-Driven Manufacturing:

We prioritize energy-efficient molding processes and recyclable materials, reducing waste and carbon footprint without compromising quality.

Your Competitive Edge:

By partnering with us, you gain access to turnkey solutions—from mold design to post-molding services (assembly, finishing)—ensuring seamless supply chain integration and cost savings.

description1